Piping Engineering

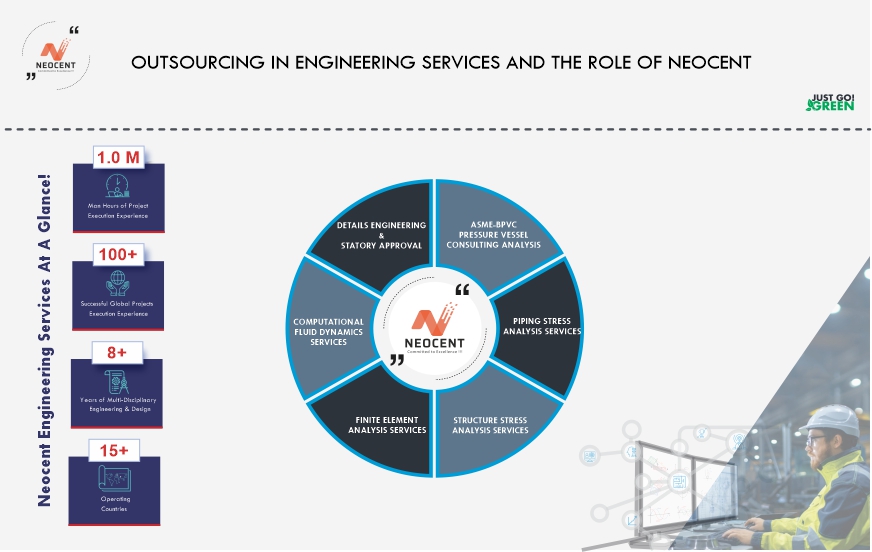

Neocent Engineering provides piping design and engineering services to engineering contractors and customers for a variety of refinery, offshore, petrochemical, water, and industrial projects with efficient piping design services solutions that meet international codes and standards. Our specialist skills help organizations from around the world to optimize the space consumption within the plants by 10-15%, especially for skid design packages installed in tight enclosures.

As a process piping engineering design company, we have a proven track record of completing projects in a stipulated time frame that offered tremendous cost benefits. So whether your requirement is for pipe spool design, process piping design, or developing a complex process plant, we provide an unmatched practical and technical acumen to make your project a success.

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry codes and standards adhered to by our Designers.

ASME B31.1, B31.3, B31.4, B31.8, B31.11, BS EN 13480, BS EN 14364, Shell DEP

Man-Hours of Project Executed

Years of Team Experience

QMS certification

Service Offering

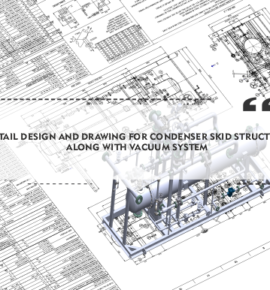

Piping Design Engineering

- Piping 2D/3D modeling

- Performing piping studies

- Preliminary piping layout, including nozzle orientation

- Preparation of preliminary & detailed GADs, BOMs/MTOs, etc.

- Preparation of equipment datasheets

- Piping design and drafting services help with the development of design and standard drawings

- Expansion of piping material specifications (PMS)

- Construction of line list according to P&ID

- Preparation of isometrics

- Final GADs/BOM

- IFC isometrics

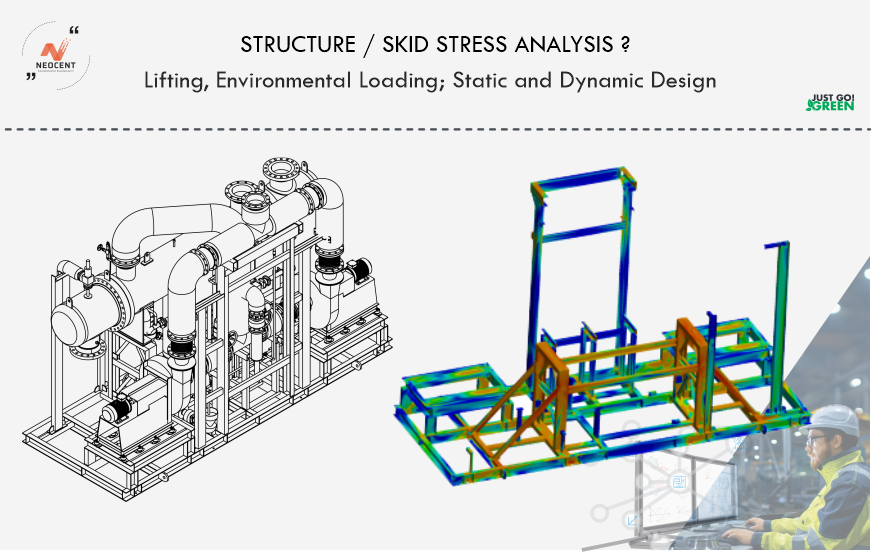

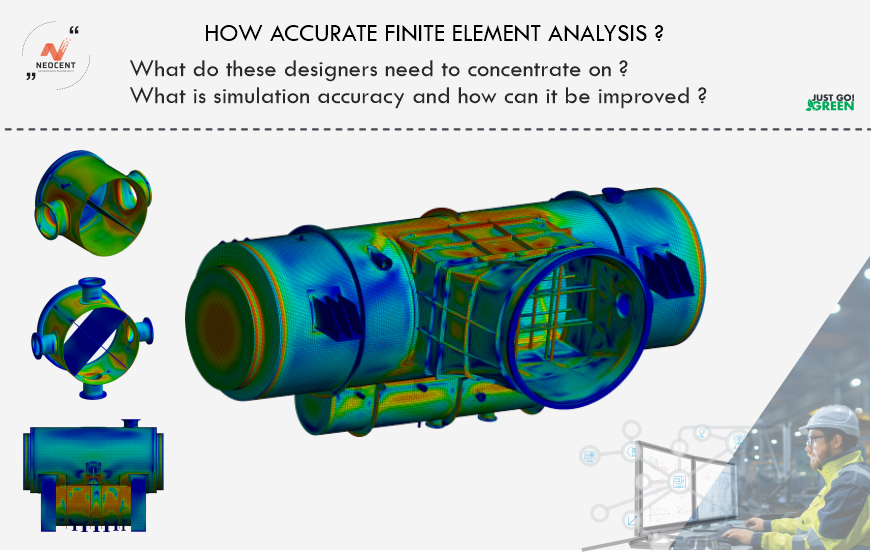

Stress Analysis

- Preparation of critical line list from the piping system design line list according to design standard

- Modeling in software such as CAESAR II and AutoPIPE form isometrics

- Prepare stress isometrics

- Nozzle datasheets

- Accurate reporting from CAESAR II and AutoPIPE

Piping Support Engineering

- Preparation of critical line list from the piping system design line list according to design standard

- Modeling in software such as CAESAR II and AutoPIPE form isometrics

- Prepare stress isometrics

- Nozzle datasheets

- Accurate reporting from CAESAR II and AutoPIPE

What To Expect When You Work With Us

It's our Forte

We have a long and wide range of project experience in carrying out a full spectrum of stress analysis for piping systems with the help of our expertise in modern tools & adherence to highest industry standards and codes.

Innovative Engineering Solutions

Through our proficiency in designing, we solve complex business challenges for optimizing space and executing faster plant upgrades.

24X7 Support

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

Scalability

We deliver the piping design and engineering solutions to both the small and large scale projects, even in a short notice period