In the fast-evolving world of industrial construction, structural steel design and detailing services form the backbone of safe, efficient, and cost-effective projects.

Trusted Engineering Design Consultancy

Specialized in FEA Engineering Services

design the future with confidence

Get

A FreeQuote

Creative digital solutions

for modern businesses

transforming ideas into exceptional digital experiences

Get

A FreeQuote

Engineering Solutions That Deliver Results

Innovation at Every Step

helping your brand stand out in a crowded market

Get

A FreeQuote

About

Established in 2019 and headquartered in India, Neocent Engineering is a premier engineering consultancy specializing in the design and analysis of coded and non-coded equipment. We provide end-to-end solutions for pressure vessels, skid packages, piping systems, heat exchangers, storage tanks, and structural steel components, catering to a wide range of industries.

With extensive expertise in Oil & Gas, Power Generation, Water Treatment, Chemical Processing, and Manufacturing, we deliver customized engineering solutions tailored to specific operational requirements and industry standards, regardless of location.

At Neocent Engineering, we combine cutting-edge technology with industry best practices to simplify complex engineering challenges. Our team of highly skilled engineers and designers ensures strict adherence to global design codes and standards, including ASME Section VIII Div. 1/2, API 650, EN 13445, PD 5500, TEMA, ASME B31.1 / B31.3 / B31.8, AISC, ASCE, EN 1993, and IS 800.

Committed to innovation, precision, and quality, we continuously push the boundaries of engineering excellence, delivering robust, high-performance solutions that drive efficiency and reliability for our clients worldwide.

Comprehensive Engineering Services & Solutions

Promo Video

the latest engineering trends and technologies world wide.

Promo Video

What Are the Benefits of Outsourcing Skid Package Design?

Outsourcing Skid Package Design provides strategic advantages, including:

- Cost savings and reduced overhead

- Faster project execution and market readiness

- Optimized layouts for seamless integration

By leveraging expert engineering support, businesses can streamline operations and enhance project efficiency.

What Industries Do We Serve?

We provide engineering solutions for Oil & Gas, Power Generation, Water Treatment, Chemical Processing, and Manufacturing industries. Our expertise ensures:

- Compliance with global engineering standards

- Optimized designs tailored to industry-specific needs

- Efficient and high-performance engineering solutions

Our commitment to quality and innovation helps businesses achieve their engineering goals with precision and reliability.

How Do We Ensure Design Accuracy and Compliance?

Our team follows ASME, API, EN, TEMA, AISC, ASCE, and IS standards to ensure high-quality designs. We achieve this through:

- Advanced FEA and CFD simulations for validation

- Strict adherence to global safety and performance codes

- Continuous design optimization for efficiency and reliability

With our expertise, we guarantee structurally sound and compliant engineering solutions.

Do We Offer Custom Engineering Solutions?

Yes, we specialize in tailored engineering services for pressure vessels, piping systems, skid packages, and structural designs. Our approach ensures:

- Solutions designed to meet specific operational needs

- Performance optimization for better efficiency

- Compliance with industry and safety standards

Every project is customized to deliver maximum value and reliability.

How Do We Support Clients Remotely?

We use secure VPN access and cloud-based collaboration tools to ensure seamless remote support. Our process includes:

- Safe and encrypted data handling

- Real-time communication and project tracking

- A dedicated project manager for streamlined coordination

This allows us to efficiently manage projects while maintaining security and confidentiality.

What Makes Us Different from Other Engineering Firms?

Our commitment to quality, innovation, and client satisfaction sets us apart. We ensure:

- Expertise Across Multiple Industries – Oil & Gas, Power, Water Treatment, and Manufacturing

- Advanced Engineering Techniques – FEA, CFD, and Structural Optimization

- Customized Solutions – Tailored to meet specific project needs and challenges

- End-to-End Support – From concept to final implementation

We prioritize delivering engineering excellence with a focus on long-term reliability and efficiency.

success

Testimonials

Neocent Engineering has been instrumental in supporting our pressure vessel and piping system designs under stringent ASME and API codes. Their deep technical expertise and commitment to meeting aggressive timelines helped us avoid costly delays during our offshore project execution. The team’s responsiveness and engineering precision set a benchmark for collaboration.

Kanti Lakhankar

We partnered with Neocent Engineering for the design and structural analysis of a complex skid-mounted heat exchanger package. Their engineers demonstrated exceptional knowledge of TEMA and ASME codes and delivered detailed engineering that passed all third-party reviews without a hitch. Truly a dependable partner for any critical process design needs.

Neil O'Keeffe

Neocent’s team supported our structural steel design with high-quality analysis in accordance with IS 800 and AISC standards. Their clarity in documentation, quick turnarounds, and willingness to incorporate last-minute client inputs made a real difference. Their structural expertise is top-notch.

Aditya Damani

Working with Neocent Engineering was seamless from start to finish. Despite being geographically distant, their understanding of EN 13445 and PD 5500 requirements was exceptional. In addition to their robust mechanical design and FEA capabilities, their CFD simulations provided valuable insights that helped us optimize flow performance and ensure compliance with critical process requirements. The attention to detail in their reports and drawing packages helped us meet both safety and compliance goals. Highly recommend them for any code-based design or simulation work.

Michael Renz

Latest Blog

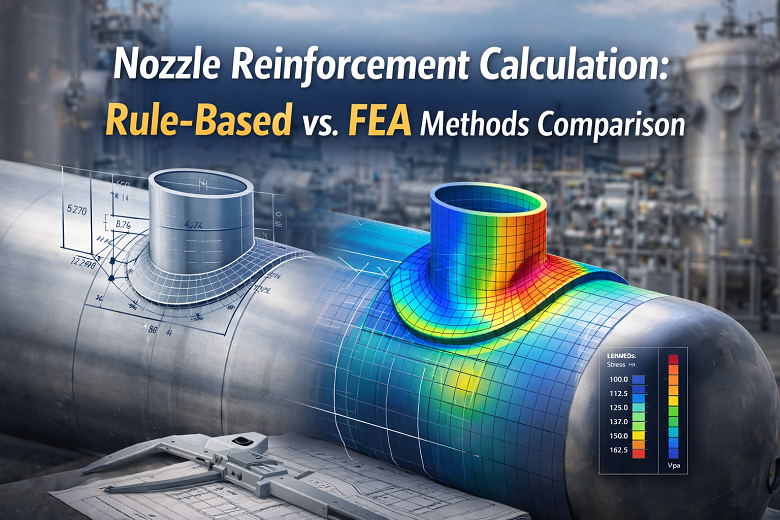

Nozzle Reinforcement Calculation: Rule-Based vs. FEA Methods Comparison

In the world of pressure vessel design, ensuring structural integrity at nozzle openings is critical to prevent failures under high pressure and temperature conditions.

Top 10 Benefits of Professional FEA Services for Pressure Vessels and Skids

In today’s competitive oil & gas, chemical processing, power generation, and water treatment industries, ASME pressure vessels and skid package designs must deliver maximum safety, performance, and cost-efficiency under extreme pressures, temperatures, and dynamic loads.

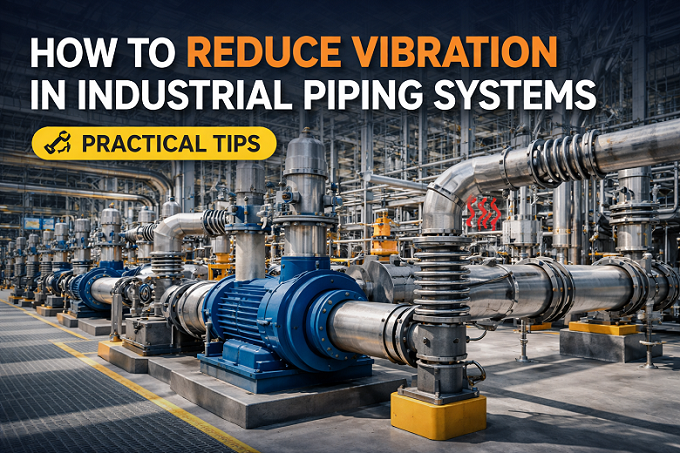

How to Reduce Vibration in Industrial Piping Systems – Practical Tips

Vibration in industrial piping systems is a common yet serious issue that can lead to fatigue failures, leaks, equipment damage, and costly downtime.

Compare Non-Coded vs ASME-Coded Pressure Vessels: Pros and Cons

In industries like oil & gas, chemical processing, power generation, and water treatment, pressure vessels play a critical role in safely containing gases or liquids under pressure.

AI in Finite Element Analysis: Reducing Errors and Time in Structural Design

In today’s competitive engineering landscape, especially in heavy industries like oil & gas, power generation, and chemical processing, structural design demands precision, speed, and reliability.

Top 10 Ways AI Will Change CFD and FEA Workflows for Indian Engineers in 2026

In 2026, Artificial Intelligence (AI) is no longer a futuristic concept for Indian engineers – it’s a practical game-changer reshaping Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) workflows.

Generative AI for CFD Modeling: The Future of Heat Exchanger Design in India

In the rapidly evolving landscape of mechanical engineering, generative AI in CFD modeling is emerging as a game-changer for heat exchanger design.

How FEA Improves Mechanical Design Accuracy in Heavy Engineering Projects

Start the blog by explaining how heavy engineering projects such as pressure vessels, skid-mounted systems, and industrial piping demand extremely high design accuracy.

Why High-Quality Structural Fabrication Matters for Industrial Projects

High-quality structural fabrication is one of the most important pillars of any industrial project, whether it’s a manufacturing plant, refinery, warehouse, power plant, or heavy-duty industrial structure.

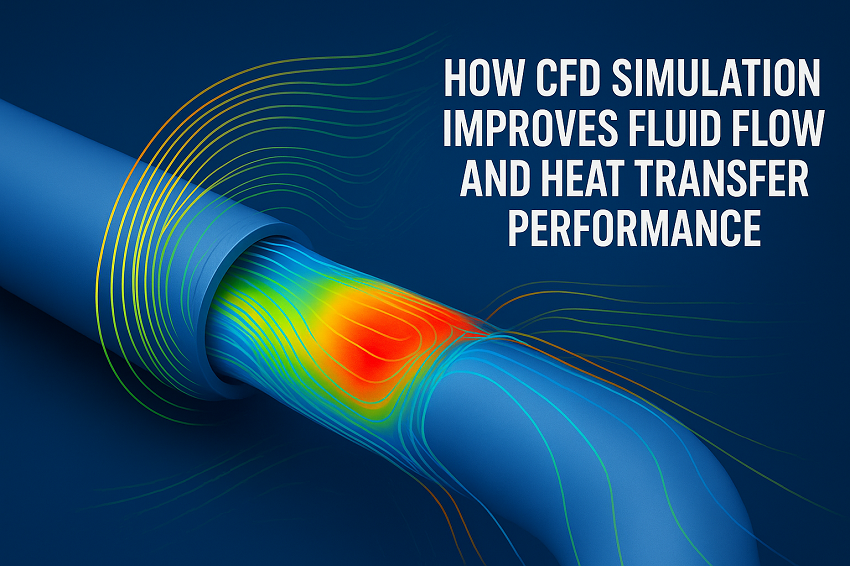

How CFD Simulation Improves Fluid Flow and Heat Transfer Performance

Computational Fluid Dynamics (CFD) has become one of the most powerful engineering tools for predicting, optimizing, and validating fluid flow, thermal behavior, and heat transfer performance across industrial applications.

How AI Is Transforming Mechanical Design Engineering in 2026: Smarter, Faster, and More Efficient

The year 2026 marks a new era in mechanical design engineering, where artificial intelligence (AI) is no longer an experimental technology but a core design enabler.

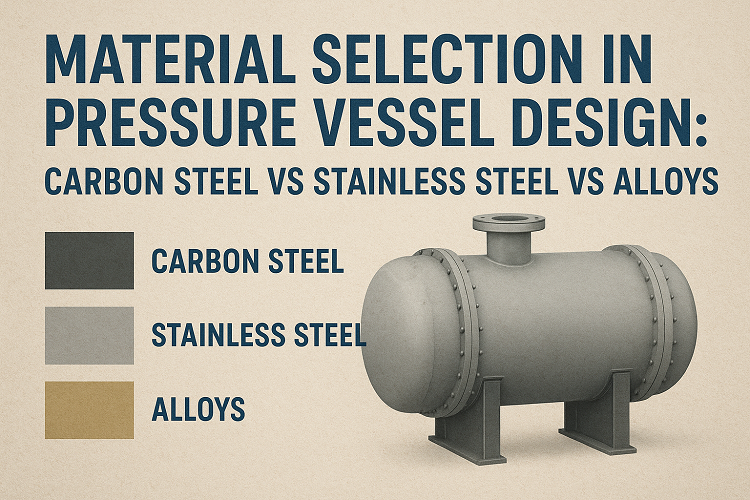

Material Selection in Pressure Vessel Design: Carbon Steel vs Stainless Steel vs Alloys

Selecting the right material is one of the most critical decisions in any Pressure Vessel Design solution. A pressure vessel doesn’t simply contain fluids or gases at high pressures

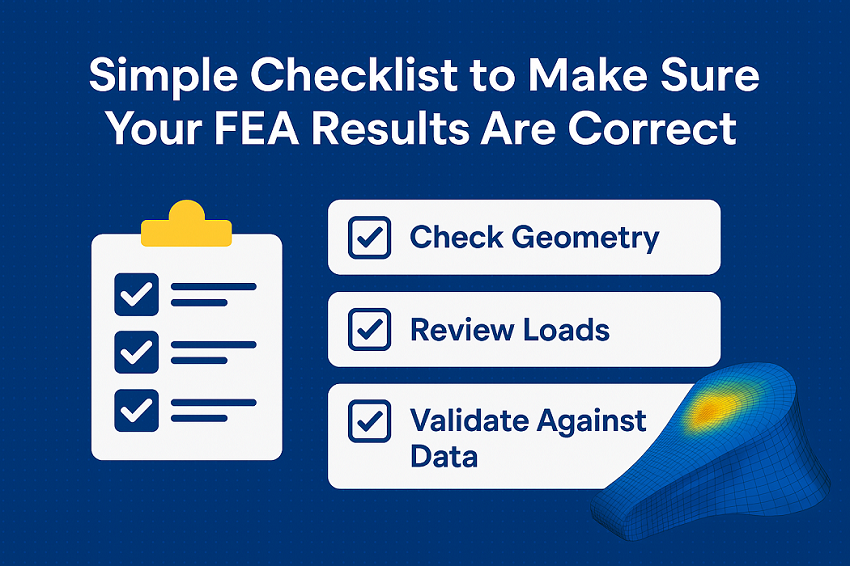

Simple Checklist to Verify Your FEA Results | FEA Consulting Service in India

Finite Element Analysis (FEA) is one of the most reliable ways to predict how a product or structure will behave under stress, temperature, or vibration.

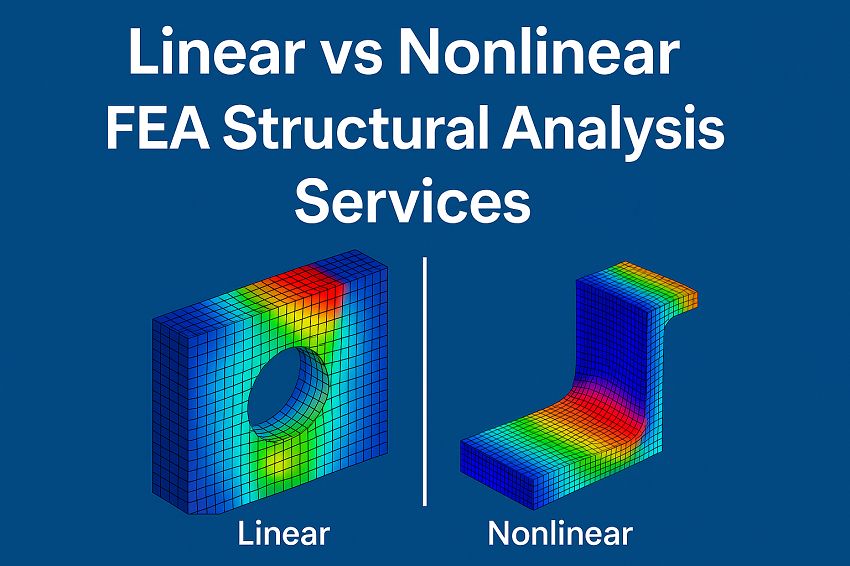

Linear vs Nonlinear FEA Structural Analysis Services – A Complete Guide for Engineers

Finite Element Analysis (FEA) has become a cornerstone of modern mechanical engineering, enabling precise simulation of complex structures before any prototype hits the shop floor.

Skid Package Standardization: Benefits and Challenges in Global Engineering Projects

In the modern industrial landscape, efficiency, reliability, and cost-effectiveness are more important than ever. One solution that has emerged to meet these demands is the skid package

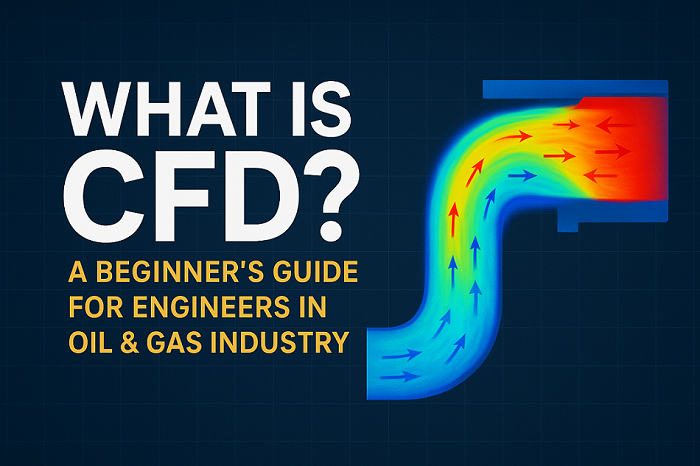

What Is CFD? A Beginner’s Guide for Engineers in Oil & Gas Industry

A Beginner’s Guide for Engineers in Oil and Gas provides an introduction to CFD as a computational method.

Engineers working in the oil and gas sector handle numerous complex responsibilities.

How Artificial Intelligence Is Revolutionizing FEA and CFD Simulations

In today’s fast-moving engineering world, speed and accuracy are everything. Engineers rely heavily on Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

Top 7 Mistakes in Pressure Vessel Design & Fabrication

Pressure vessels are used in many industries. Oil and gas, chemicals, pharma, power plants… you name it. They work under high pressure. And sometimes in tough conditions. Even small mistakes in design or making them

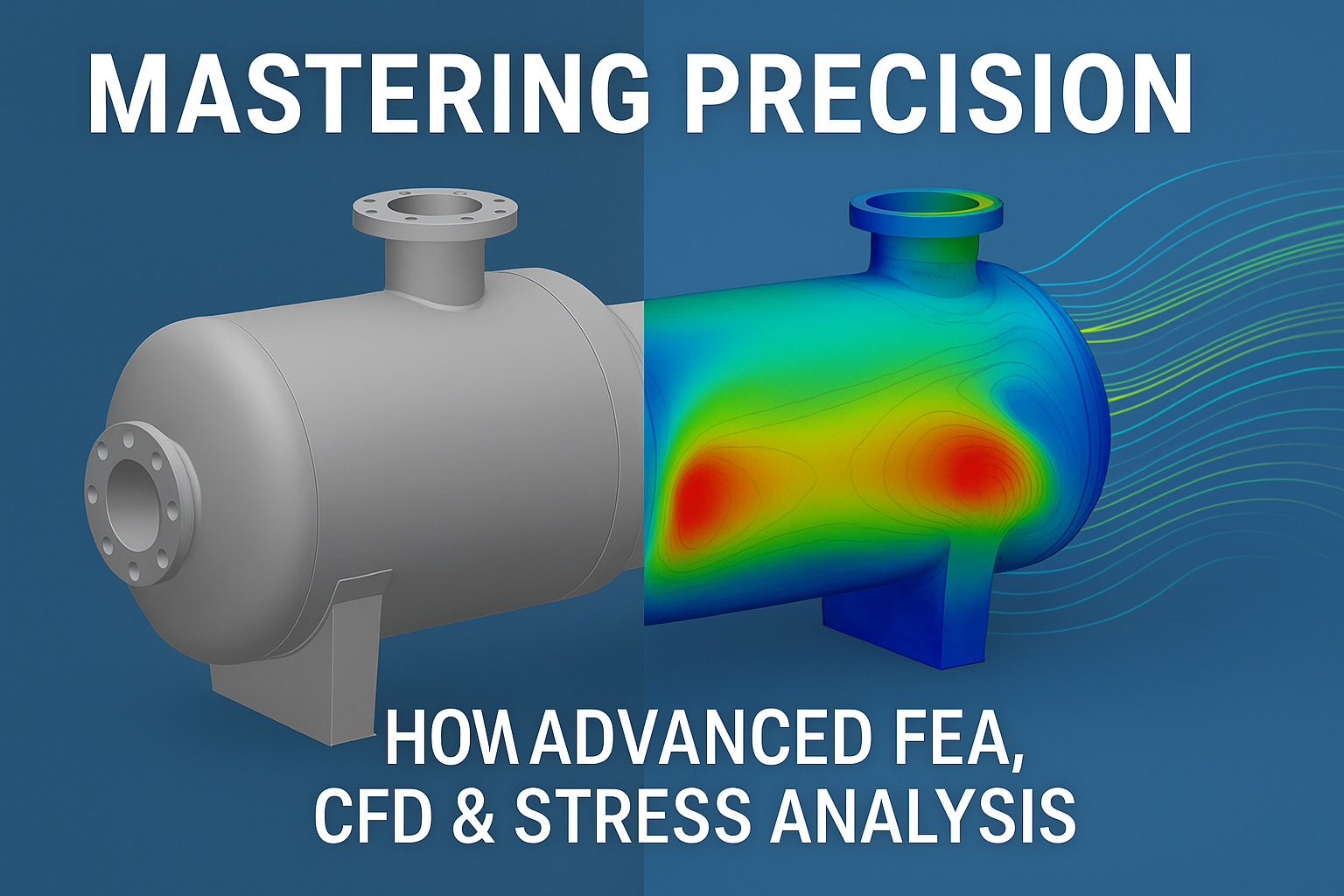

Mastering Precision: How Advanced FEA, CFD & Stress Analysis Future-Proof Engineering Projects

Engineering excellence today hinges on foresight, accuracy, and efficiency. Leveraging Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD)