Introduction

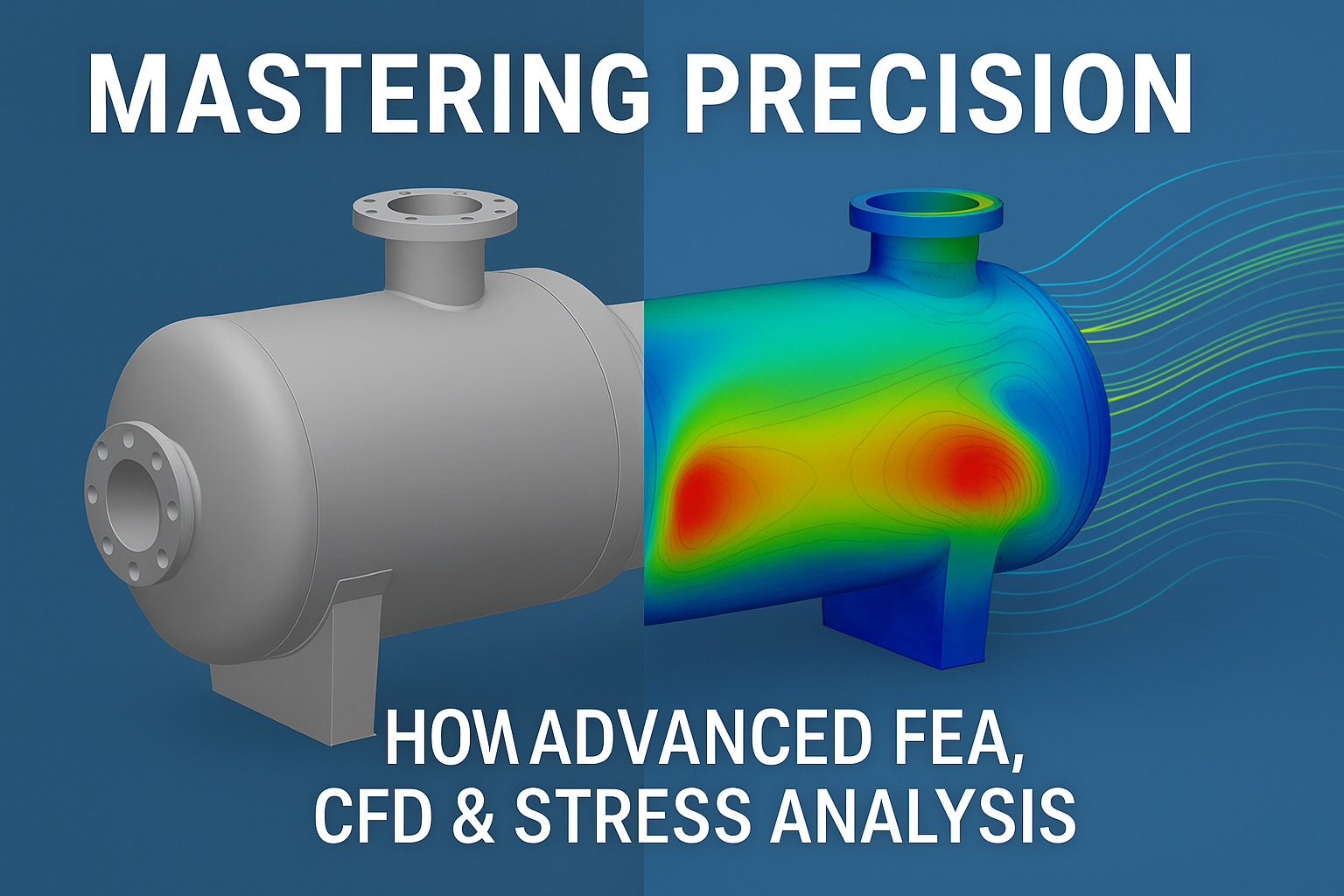

Engineering excellence today hinges on foresight, accuracy, and efficiency. Leveraging Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and piping stress analysis enables companies to anticipate failures, optimize designs, and accelerate time-to-market—all without brand names, just authority.

Why These Analysis Tools Matter

Finite Element Analysis (FEA)

-

- Predict structural behavior under loads using mesh-based models.

-

- Detect stress hotspots, deformation, or fatigue before manufacturing.

-

- Reduce prototypes, helping cut both time and material costs.

Computational Fluid Dynamics (CFD)

-

- Simulate fluid flow, heat transfer, and pressure dynamics.

-

- Improve efficiency and product performance virtually, saving on testing.

-

- Optimize designs for aerodynamics, cooling, or chemical processes.

Piping Stress Analysis

-

- Identify critical stress points in piping due to pressure, thermal expansion, and external forces.

-

- Ensure safety and longevity of piping systems—especially key in oil, gas, and process industries.

-

- Support compliance with codes like ASME, avoiding costly regulatory hurdles.

Advantages of Design-Driven Analysis

Higher Safety Margin

Early failure detection means safer, more reliable systems—critical in high-risk sectors.

Cost & Resource Efficiency

Simulations replace physical trials, cutting waste and speeding up decisions.

Faster Development Cycles

Virtual testing allows rapid iteration—crucial for industries with tight deadlines.

Regulatory Readiness

When projects align with international codes, approvals become smoother.

Industry Applications That Benefit Most

-

- Industrial Manufacturing

Optimize heavy machinery and component designs before prototyping.

- Industrial Manufacturing

-

- Oil & Gas Infrastructure

Ensure safe pipeline and vessel operation through accurate stress simulations.

- Oil & Gas Infrastructure

-

- Power Generation & Renewables

Improve thermal and fluid efficiency in boilers, turbines, and HVAC systems.

- Power Generation & Renewables

-

- Chemical & Process Plants

Develop reliable piping networks, minimizing downtime and enhancing safety.

- Chemical & Process Plants

Conclusion

Precise simulations and computational engineering tools are more than buzzwords; they’re strategic investments. By blending Finite Element Analysis, CFD, and piping stress analysis, organizations can deliver safer designs, faster timelines, and smarter outcomes.

With a title that speaks to mastery and future-readiness, this blog positions your platform as both an educational resource and a trusted technical authority.

FAQs

Q1. What is the role of FEA in modern engineering projects?

Finite Element Analysis (FEA) helps engineers predict stress, strain, and failure points, ensuring safer and more efficient designs.

Q2. How does CFD improve engineering design?

Computational Fluid Dynamics (CFD) simulates fluid flow, heat transfer, and aerodynamics, reducing trial-and-error and speeding up product development.

Q3. Why is piping stress analysis important in industrial projects?

It ensures pipelines can withstand pressure, temperature changes, and vibrations, preventing leaks, failures, and safety risks.

Q4. What are the benefits of combining FEA, CFD, and stress analysis?

Together, they provide a holistic view of performance, optimize designs, reduce costs, and improve reliability across industries.

Q5. How do these simulations support future-proof engineering?

They enable predictive insights, minimize risks, ensure compliance with global standards, and deliver long-term project sustainability.

Krupal Patel

Krupal Patel is the CEO of Neocent Engineering Pvt. Ltd., Ahmedabad, specializing in advanced engineering solutions. With over 8 years of expertise in Product Design, FEA, CFD, and ASME-BPVC stress analysis, he has successfully delivered high-precision projects across pressure vessels, piping, and structural systems.