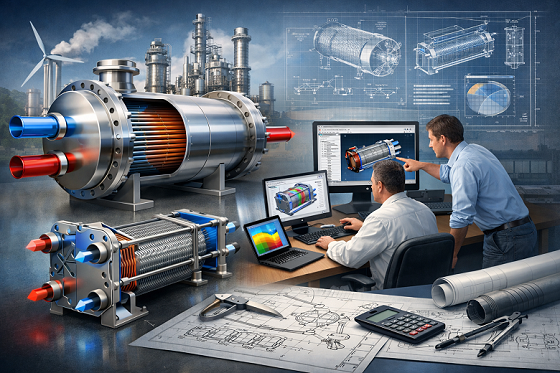

Heat Exchanger Design Consulting Services

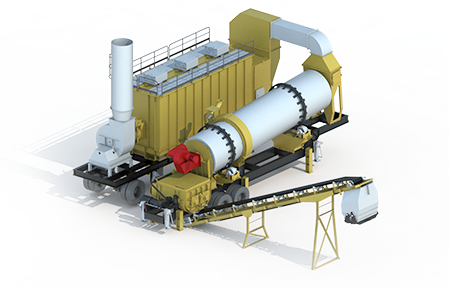

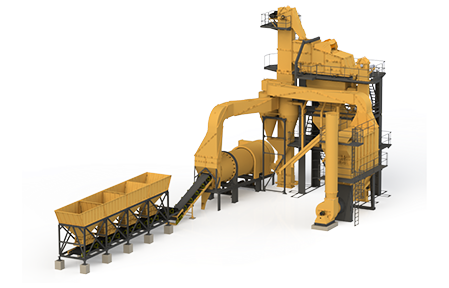

At NEOCENT, we deliver Heat Exchanger Design & Detailing Service India that combines precision, efficiency, and reliability for every project. As one of the trusted Heat Exchanger Design Consulting Services Ahmedabad, we provide designs that maximise thermal performance while remaining cost-effective. From shell-and-tube heat exchangers and plate heat exchangers to specialised process units, our engineering team ensures your systems are safe, efficient, and durable.

No two heat exchanger projects are ever the same. That’s why our heat exchanger design consulting services India approach analyses every aspect — from thermal loads, fluid dynamics, pressure drops, and material compatibility to operational and environmental conditions. We don’t rely on generic templates; we create solutions that match your project’s unique demands. From concept to commissioning, our team guarantees every unit meets your performance expectations and international standards.

Heat Exchanger Design Experts

Our team of experienced engineers handles everything from basic shell-and-tube layouts to complex customised heat exchangers. We model, analyse, and optimise your system so it’s thermally efficient, structurally sound, and economical.

With strong expertise in global design codes, we deliver clear 3D models, design reports, and detailed drawings for quick client approval and fabrication readiness.

Our heat exchanger engineering solutions cover a wide range of applications – chemical plants, process industries, oil & gas, power stations, and more. Using tools like ANSYS, HTRI, and advanced finite element analysis for heat transfer, we predict real-world performance and design accordingly. NEOCENT is recognised among Popular Heat Exchanger Designers in Ahmedabad for our consistent quality and innovation.

Our Key Heat Exchanger Engineering Capabilities

Heat Exchanger Design & Detailing

Thermal & Flow Analysis

3D Modelling & Visualisation

Thermal Stress & Vibration Analysis

Shell & Tube, Plate & Special Heat Exchanger Designs

Pressure Drop & Efficiency Optimisation

Retrofitting & Upgradation Solutions

Finite Element Analysis for Heat Transfer

Heat Exchanger Animation & Visualisation

We create detailed animations that bring your heat exchanger project to life. These animations clearly show how your design behaves under operational conditions, helping with client presentations, design approvals, and operator training.

By combining technical accuracy with high-quality visuals, we make complex thermal systems easy to understand and evaluate before fabrication begins — saving time, effort, and cost.

Why Choose NEOCENT for Heat Exchanger Design Services?

Save engineering hours with accurate, fabrication-ready drawings

Detect thermal stress and flow issues early — avoid rework and downtime

Multi-industry experience – chemical, power, oil & gas, and process plants

Compliant with ASME, TEMA, and other international standards

Clear 3D visuals for design approvals and presentations

Optimise layouts to reduce material and energy use

Experienced Heat Transfer Consulting Services provider with global reach

Our Engineering Strengths in Heat Exchanger Systems

Thermal & Flow Analysis

We assess how heat and fluid flow affect your system to ensure optimal performance and efficiency.

Pressure Drop & Stress Studies

We study how pressure variations and thermal stresses impact the heat exchanger — ensuring long-term reliability.

Finite Element & Flow Simulations

Our engineers simulate operational performance to prevent thermal fatigue and mechanical failure over time.

Advanced 3D Modeling

We use tools like ANSYS, HTRI, and AutoCAD to develop detailed and precise 3D models that make decision-making faster and easier.

Heat Exchanger Design & Analysis

Services We Offer

Thermal Performance Calculations

From temperature gradients to fluid flow behaviour, we calculate how your heat exchanger performs under all conditions.

Design & Detailing

We create precise layouts for shell, tube, plate, and specialised heat exchangers.

Fabrication & Construction Drawings

Every connection, joint, and component is clearly detailed – simplifying fabrication and assembly.

Finite Element Analysis (FEA)

We perform advanced simulations using finite element analysis for heat transfer to identify stress points and optimise designs.

Retrofitting & Upgradation Services

Need to enhance an existing heat exchanger? Our team provides reinforcement and upgrade solutions for older or overloaded units.

Why Pick NEOCENT for Heat Exchanger Projects?

Because we focus on performance, practicality, and safety. Our engineers deliver solutions that are technically sound, economically smart, and construction-ready — so your project stays on schedule and within budget.

- Trusted Heat Exchanger Design Consulting Services Ahmedabad provider

- Complete start-to-finish heat exchanger design service

- Advanced analysis tools and international design standards

- Faster turnaround with fewer revisions

- Proven expertise across chemical, industrial, and process sectors