Introduction

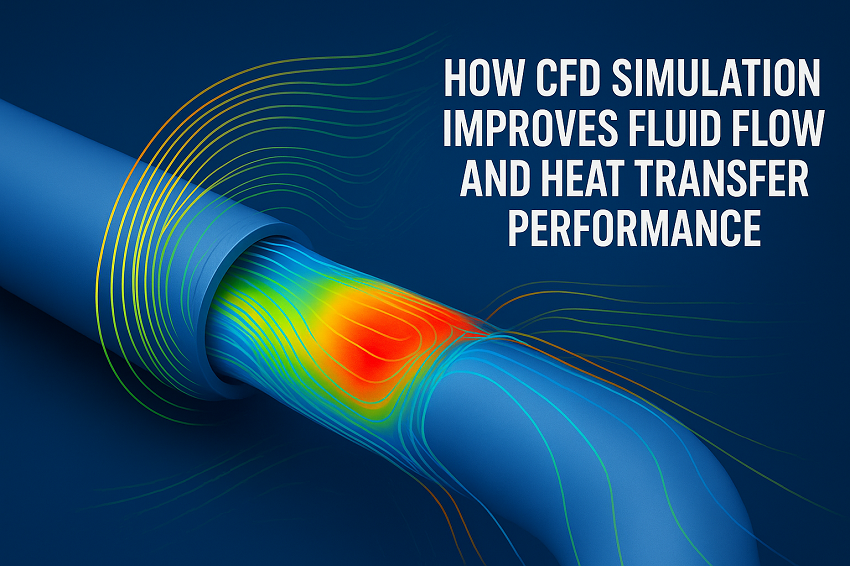

Computational Fluid Dynamics (CFD) has become one of the most powerful engineering tools for predicting, optimizing, and validating fluid flow, thermal behavior, and heat transfer performance across industrial applications. From complex process equipment to HVAC systems, heat exchangers, combustion chambers, and high-pressure pipelines, CFD simulation helps engineers identify inefficiencies, reduce design errors, and enhance system reliability—long before physical prototyping.

In this blog, we explore how CFD improves both fluid flow and heat transfer performance, why it is essential for modern engineering projects, and where businesses can leverage CFD consulting services for rapid, data-driven decision-making.

1.What Is CFD and Why It Matters Today?

CFD (Computational Fluid Dynamics) uses numerical methods and algorithms to simulate fluid behavior, thermal transport, and energy exchange across different operating conditions.

Key benefits of CFD simulation

- Predicts flow distribution, pressure drop, and turbulence intensity

- Improves heat transfer efficiency through accurate temperature mapping

- Identifies design flaws before manufacturing

- Reduces project cost by eliminating excessive prototyping

- Enables faster R&D and shorter time-to-market

Industries such as oil & gas, pharmaceuticals, automotive, chemical processing, HVAC, energy, and manufacturing rely heavily on CFD to ensure better performance, safety, and compliance.

How CFD Improves Fluid Flow Performance

Fluid flow behaviour is critical for equipment like pumps, pipelines, valves, manifolds, blowers, ducts, scrubbers, separators, and reactors. Poor flow distribution leads to pressure losses, vibration, cavitation, erosion, and higher energy consumption.

CFD enables engineers to visualize what is happening inside the system—things that cannot be seen using manual engineering calculations.

2.1 Flow Pattern Analysis

CFD identifies:

- Recirculation zones

- Flow separation

- Velocity gradients

- Dead zones

- Jet impingement

This helps in optimizing geometry for smooth, uniform flow.

2.2 Reducing Pressure Drop and Improving System Efficiency

High pressure drop increases pumping power and operational costs.

CFD helps optimize:

- Pipe routing

- Nozzle geometry

- Valve placement

- Manifold design

- Bends and elbows

2.3 Turbulence Modeling for Accurate Predictions

Using advanced models such as k-ε, k-ω, SST, LES, and DES, CFD predicts:

- Turbulence intensity

- Mixing efficiency

- Swirl behavior

- Flow instabilities

This is especially important for high-speed, high-temperature, or multiphase flows.

2.4 Particle, Erosion & Multiphase Flow Analysis

CFD evaluates:

- Solid particle trajectories

- Erosion zones

- Liquid-gas separation

- Slurry flows

- Phase change

This helps protect equipment from premature failure.

How CFD Enhances Heat Transfer Performance

Heat transfer affects systems like heat exchangers, heaters, coolers, electronic enclosures, boilers, condensers, radiators, and thermal management systems. Inefficient thermal design leads to hotspots, overheating, thermal shocks, and early component failure.

3.1 Accurate Temperature Distribution Mapping

CFD helps engineers visualize temperature gradients to identify:

- Hot spots

- Cold zones

- Uneven heat distribution

- Thermal bottlenecks

This ensures the design meets thermal performance requirements.

3.2 Improving Heat Exchanger Efficiency

CFD helps optimize:

- Tube layout

- Fin geometry

- Baffle arrangement

- Flow distribution

- Heat transfer coefficient

This reduces energy consumption and increases heat recovery.

3.3 Convection, Conduction & Radiation Modeling

CFD handles all three modes of heat transfer:

- Forced convection (fans, blowers, pumps)

- Natural convection (buoyancy-driven flows)

- Radiative transfer (furnaces, heaters, combustion chambers)

This allows engineers to design thermally efficient systems for even extreme environments.

3.4 Thermal Management for Electronics & Batteries

CFD optimizes:

- Cooling channel design

- Heat sink geometry

- Airflow paths

- Liquid cooling systems

Essential for industries like EVs, power electronics, and telecom.

Industries That Benefit from CFD Simulation

CFD provides massive benefits across:

- Oil & Gas: Erosion, multiphase flow, separators, combustion

- Chemical Processing: Mixing, reaction kinetics, heat transfer

- HVAC: Indoor airflow, ventilation optimization, cooling performance

- Automotive: Aerodynamics, thermal management, combustion

- Energy & Power: Boilers, turbines, heat exchangers

- Pharmaceuticals: Cleanroom design, airflow distribution

- Manufacturing: Cooling channels, mold design, fumes extraction

5. Why CFD Is Better Than Manual Calculations

Traditional engineering calculations assume ideal conditions.

But CFD accounts for:

- Real operating conditions

- Turbulence

- Complex geometries

- Temperature-dependent properties

- Transient behavior

- Multiphase interactions

CFD transforms assumptions into accurate, visualized engineering predictions.

6. How Neocent Engineering Helps With Advanced CFD Consulting

Neocent Engineering provides end-to-end CFD consulting services to help organizations improve system performance, reduce failures, and optimize design.

Our CFD capabilities include:

- Fluid flow analysis

- Heat transfer & thermal analysis

- Multiphase flow modeling

- Turbulence modeling

- HVAC & ventilation simulation

- Combustion analysis

- Erosion & particle flow

- Fluid-structure interaction (FSI)

- Heat exchanger optimization

- Custom equipment simulation

Our engineers help you reduce project risk, improve product reliability, and achieve maximum efficiency using advanced simulation tools and ASME/industry-standard methods.

Conclusion

CFD simulation is no longer optional—it is a critical engineering tool for improving fluid flow, thermal performance, and overall system reliability. By providing accurate insights into real-world physics, CFD helps organizations reduce costs, accelerate innovation, and design safer, more efficient products.

If you’re looking to enhance your system performance, reduce failures, or optimize equipment design, partnering with expert CFD consultants like Neocent Engineering ensures your project achieves the highest engineering standards.

FAQ Section

1. What is CFD simulation and why is it important for fluid flow and heat transfer analysis?

CFD (Computational Fluid Dynamics) is a numerical technique used to analyze fluid flow, heat transfer, pressure distribution, and related physical phenomena. It is important because it helps engineers visualize and optimize system performance without physical prototypes, reducing cost, development time, and potential design errors. CFD provides deeper insights into flow behavior, turbulence, boundary layer effects, and thermal efficiency—supporting smarter engineering decisions.

2. How does CFD improve heat transfer performance in industrial systems?

CFD improves heat transfer by identifying thermal hotspots, predicting temperature gradients, optimizing cooling/heating geometry, and analyzing conduction, convection, and radiation effects. Industries use CFD to enhance heat exchangers, boilers, HVAC systems, cooling ducts, electronic cooling, and process equipment—resulting in better thermal efficiency and reduced energy consumption.

3.Which industries benefit the most from CFD analysis?

Industries that rely heavily on fluid flow and thermal management benefit the most, such as:

- Oil & Gas

- Chemicals & Petrochemicals

- HVAC & Building Engineering

- Power Generation

- Automotive & Aerospace

- Pharmaceuticals & Food Processing

- Renewable Energy

These sectors use CFD for flow assurance, mixing, pressure drop minimization, combustion analysis, ventilation optimization, and safety improvements.

4. What input data is required to perform a high-quality CFD simulation?

A robust CFD analysis requires:

- Geometry or CAD model

- Material properties (fluid viscosity, density, thermal conductivity, etc.)

- Boundary conditions (velocity, pressure, temperature, heat flux)

- Operating conditions (flow rate, turbulence intensity)

- Mesh quality settings

- Solver selection (RANS, LES, multiphase, etc.)

5. Can CFD reduce product development cost and time?

Yes. CFD significantly reduces both cost and time by minimizing the need for physical testing, prototypes, and repeated manufacturing trials. Engineers can evaluate multiple design iterations virtually, optimize performance, and eliminate flaws early. This accelerates decision-making and improves design reliability, safety, and performance efficiency, especially for complex industrial systems.

Krupal Patel

Krupal Patel is the CEO of Neocent Engineering Pvt. Ltd., Ahmedabad, specializing in advanced engineering solutions. With over 8 years of expertise in Product Design, FEA, CFD, and ASME-BPVC stress analysis, he has successfully delivered high-precision projects across pressure vessels, piping, and structural systems.