Introduction: Why Checking Your FEA Results Matters

Finite Element Analysis (FEA) is one of the most reliable ways to predict how a product or structure will behave under stress, temperature, or vibration. From automotive components to pressure vessels and bridges, engineers rely on FEA to make design decisions before building prototypes.

However, here’s the catch — an inaccurate FEA result is worse than having no analysis at all. Even a minor mistake in geometry, load, or material property can lead to faulty conclusions, wasted cost, and potential design failure.

That’s why it’s essential to have a clear checklist to ensure your FEA results are correct and trustworthy.

Whether you’re an engineer handling simulation in-house or working with an FEA consulting service in India, following this checklist can help you interpret data accurately and make confident design choices.

Start with the Basics – Understand the Real Problem

Before diving into meshing and solver settings, start by defining the real engineering question your FEA analysis should answer.

Ask yourself:

- Are you checking for static strength, vibration, or fatigue life?

- Do you need local stress data or global deformation trends?

- Is your goal design validation or failure prediction?

Without clarity, you might set up a model that solves the wrong problem. For example, if your goal is to understand buckling behavior but you only run a static linear analysis, your results will be meaningless.

Many FEA services recommend starting every project with a written “simulation objective statement.” It helps align model setup, solver selection, and boundary conditions with the actual engineering challenge.

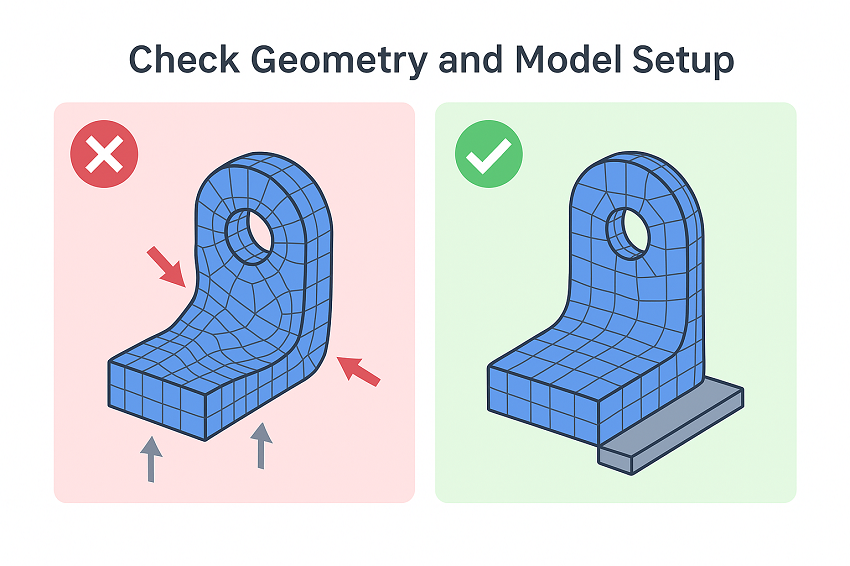

Check Geometry and Model Setup

Geometry is the foundation of every FEA model. Even small mistakes — a missing fillet, intersecting surfaces, or an unconnected body — can produce unrealistic stress concentrations or zero-load conditions.

Geometry is the foundation of every FEA model. Even small mistakes — a missing fillet, intersecting surfaces, or an unconnected body — can produce unrealistic stress concentrations or zero-load conditions.

Simplifying geometry is normal, but make sure it doesn’t remove features critical to stress flow. For example, a hole or notch can double the local stress, so removing it might make your results overly optimistic.

A professional FEA consulting company in India always performs geometry healing and simplification audits before meshing. Use CAD repair tools to check for gaps, duplicate faces, and unmerged solids.

Verify Material Properties

Material properties have a direct impact on stress and deformation results. Using incorrect or incomplete data can skew your model by more than 20%.

According to a ResearchGate 2022 study, 25% of FEA errors come from wrong or assumed material inputs (Source).

Before running your simulation:

- Verify Young’s modulus, Poisson’s ratio, and yield/tensile strength.

- Use data from verified databases like MatWeb or ASM International.

- For temperature-dependent studies, ensure you’re using nonlinear material models.

FEA tools can’t fix bad inputs — as experts often say, “Garbage in, garbage out.” So double-check your material card before clicking “solve.”

Review Loads and Boundary Conditions

Loads and constraints represent real-world behavior — and they’re the biggest source of error if set incorrectly.

Common issues include:

- Fully fixing parts that should move slightly.

- Missing contacts or friction between interfaces.

- Applying loads at points instead of realistic surfaces.

For example, a bracket fixed entirely instead of only at bolt holes may show unrealistically low stress. Always visualize load directions, magnitudes, and constraint points in your pre-processor.

In professional FEA consulting services in India, engineers perform a “boundary sanity check” to confirm that reactions and applied loads balance — an easy way to catch setup errors early.

Assess Mesh Quality and Refinement

Mesh quality is one of the strongest indicators of result accuracy. A good mesh ensures correct stress gradients and minimizes numerical errors.

Keep an eye on:

- Element size — refine mesh near stress concentrators.

- Aspect ratio — avoid long, distorted elements.

- Skewness — keep elements close to ideal shapes.

📊 ANSYS whitepaper (2023) found that poor mesh can increase numerical errors by 30–40% (Source).

Always perform mesh convergence testing — re-run the same analysis with finer mesh and check if key results (stress, displacement) change by less than 5%. If results fluctuate, your mesh isn’t refined enough.

Check Code Compliance and Design Standards

FEA doesn’t replace design codes — it complements them.

Even if your simulation shows low stress, your design may still fail to meet standards like ASME Section VIII, API 579, or Eurocode.

Use FEA results to verify compliance rather than assume it. For example, ASME mandates specific stress categorization (primary, secondary, peak) which many simulations don’t automatically classify.

A reliable FEA service in India ensures every report references applicable codes and explains how simulation outcomes satisfy design limits.

Ask for Numeric Verification — Not Just Colorful Images

A colorful stress plot might look impressive, but colors can mislead.

Real verification lies in numbers — maximum stress values, factor of safety, deflection, and reaction forces.

If you’re outsourcing to an FEA consulting company in India, ask for:

- Node-based stress values.

- Mesh convergence graphs.

- Force balance summaries.

- Tabulated results next to color contours.

This numeric verification separates professional engineering reports from “visual-only” presentations.

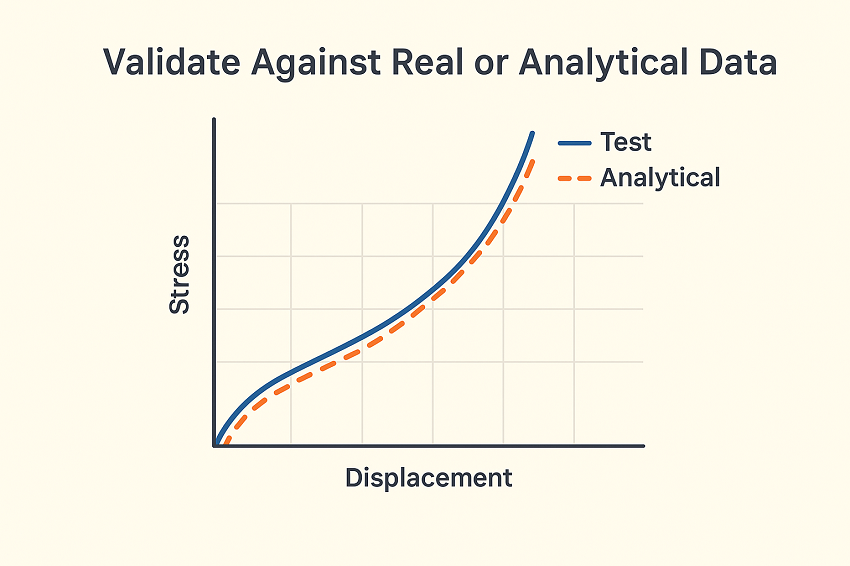

Validate Against Real or Analytical Data

FEA is a numerical approximation — always validating results against hand calculations or test data.

Even a simple beam bending equation can serve as a baseline to confirm your FEA’s credibility.

Example: If your theoretical stress is 150 MPa but FEA predicts 155 MPa, the correlation is excellent. But if it shows 300 MPa, there’s a setup issue.

Professional FEA consulting services in India regularly perform validation studies comparing simulation vs. experimental results, typically targeting less than 10% deviation.

Review the Report Presentation

A good FEA report is not just about images — it’s about clarity and traceability.

Check that your report includes:

- Model purpose and assumptions

- Geometry simplifications

- Material and load data

- Mesh quality metrics

- Key results and code compliance summary

The report should tell a clear story from setup to conclusion. Many engineering clients now request “executive summaries” that translate technical findings into business decisions.

Red Flags to Watch Out For

When reviewing your FEA report, be alert to these warning signs:

- Extremely high stress spikes at boundaries — often unrealistic constraints.

- Zero reaction forces — missing loads or contacts.

- Overly smooth stress plots — possibly coarse mesh.

- Lack of validation section — incomplete analysis.

If you spot these, consult an expert or a certified FEA service provider in India for revalidation.

Conclusion: Trust Data, Not Colors

FEA is one of the most powerful tools in modern engineering — but only when used correctly. Every simulation should tell a story backed by physics, logic, and verified data — not just attractive color plots. By following this checklist — from geometry checks to load validation, mesh refinement, and code compliance — you can make sure your FEA results are technically sound and defensible.

And if your project involves complex non-linear or safety-critical analysis, consider partnering with Neocent Engineering, a leading FEA consulting service in India. Their expert team ensures that every model, mesh, and result is built on solid engineering principles — giving you data you can trust and confidence in every design decision.

Frequently Asked Questions (FAQs)

- How can I tell if my FEA results are reliable?

Reliable FEA results come from accurate model setup, proper mesh refinement, and realistic boundary conditions. Always validate your results against experimental or analytical data to ensure accuracy. - Why is mesh quality so important in FEA analysis?

Mesh quality directly impacts the accuracy of your results. A poor or overly coarse mesh can lead to misleading stress concentrations or missed failure zones. A good rule is to perform a mesh convergence study before finalizing results. - What are the most common mistakes in FEA modeling?

Common mistakes include incorrect boundary conditions, wrong material properties, and oversimplified geometry. These issues can easily distort results, making your analysis unreliable. - How often should I verify FEA models during a project?

Verification should be continuous—especially after major design changes. Every update to geometry, load, or boundary condition requires a recheck to maintain accuracy and compliance with standards. - Can outsourcing to an FEA consulting service in India improve accuracy?

Yes. Expert FEA consulting services in India often have access to advanced simulation tools and domain specialists who ensure your analysis meets international standards while reducing cost and project time. - What’s the best way to validate FEA results?

The best approach is to compare your simulation output with experimental test data or analytical solutions. This ensures your FEA service is producing results grounded in real-world performance.

Krupal Patel

Krupal Patel is the CEO of Neocent Engineering Pvt. Ltd., Ahmedabad, specializing in advanced engineering solutions. With over 8 years of expertise in Product Design, FEA, CFD, and ASME-BPVC stress analysis, he has successfully delivered high-precision projects across pressure vessels, piping, and structural systems.