Piping Design & Stress Engineering Solutions

At NEOCENT, we take care of piping design and stress analysis tailored to your project needs. Our piping stress engineering team combines practical experience with the right tools to design systems that are safe, strong, and efficient. Doesn’t matter if it’s an oil and gas industry plant, a power station, or any industrial site — we keep it cost-effective and reliable.

No two piping systems are the same. That’s why our team never copies old blueprints. We study your layout, the loads, temperature changes, and even the ground conditions for underground piping stress analysis. From concept to final design, we plan everything carefully and make sure the stress analysis of piping systems is spot on.

Piping Stress Engineering Experts

Our engineers work with piping systems of every scale. From simple networks to highly complex piping setups, we’ve handled them all. We create clear 3D models with layouts, supports, and fittings so you can see exactly how everything comes together.

Our piping design and stress analysis services include strength checks, column piping stress analysis, thermal expansion studies, and vibration tests. We use advanced tools like CAESAR I & II to simulate real-world conditions, ensuring reliable results for both piping stress analysis for power plants and piping design and stress analysis for the oil and gas industry.

Our Key Piping Design Capabilities

Piping Stress Engineering

Column Piping Stress Analysis

Underground Piping Stress Analysis

Piping Layout & Detailing

Piping Design for the Oil and Gas Industry

Piping Stress Analysis CAESAR I & II

Industrial Piping Engineering

Piping Stress Analysis for Power Plants

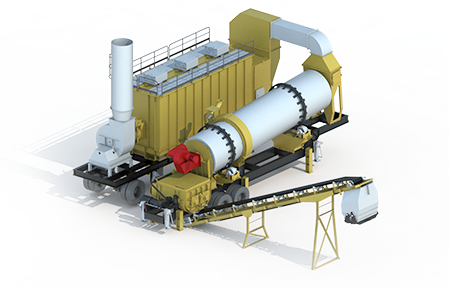

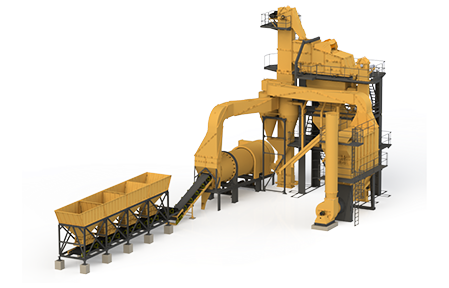

Piping Engineering Animation Videos

We make piping animation videos that show how your system actually works. These videos are super useful for client approvals, training, and even marketing. They show real-time flow, how components interact, and how the system handles stress.

By blending technical data with visuals, we give you clear insights before anything is built. You see the setup from all angles, which makes decisions faster and way easier.

Why Choose NEOCENT for Piping Design Services?

Save time at the site with fabrication-ready drawings

Spot design issues early, skip costly rework

smarter layouts that reduce material waste

smart, efficient, and easier-to-maintain designs

Clear visuals for quick client approvals

Compliance with industry codes and standards

Engineers who know piping in mechanical engineering inside-out

Our Engineering Strengths in Piping Systems

Thermal & Stress Analysis

We study how heat and pressure affect the pipes so nothing fails in the field. Our designs handle expansion, contraction, and loads like pros.

Dynamic Load & Vibration Response

We check how pipes react when machines vibrate, shake, or hit them. Smooth operation, no surprises.

Fatigue & Crack Prevention

We run repeat-cycle simulations to predict weak spots before they happen. Longer life, fewer breakdowns.

Piping Modelling in CAD

We use CAESAR II, SolidWorks, and AutoCAD to create accurate 3D piping models. Super clear, easy to understand, and fast to approve.

Piping Design & Stress Analysis Services We Offer

Neocent Engineering Offers

Static and Dynamic Load Calculations

We figure out how much your piping can handle, both at rest and under stress. No collapse, no problem.

Piping Layout and Equipment Support

Think of us as puzzle masters — we place everything so it fits, flows, and lasts without awkward stress on joints.

Fabrication-Ready Drawings

We deliver piping drawings with every weld, flange, and support clearly marked. Even first-time fabricators can follow along.

Vibration & Fatigue Testing

We run simulations that mimic real-world conditions to find out where issues might pop up over time.

Custom & Composite Design Support

Special materials? Complex setups? We design around your needs, not the other way around.

Why Pick NEOCENT for Piping Projects? to Neocent Engineering

Honestly, we just save you time, money, and unnecessary stress on your piping projects. We deliver practical designs, clear reports, and quick turnarounds so you never get stuck guessing.

- Trusted piping engineering company with global support

- Complete start-to-finish project handling

- Industry approved software and tools

- Faster project cycles with fewer revisions

- Experience across oil & gas, power plants, and industrial piping engineering