Skid Package Design & Engineering Solutions

Okay, so at NEOCENT, we help with skid package design and engineering solutions that work how you need them to. Our smart (but chill) skid engineers use the right tools and their hands-on experience to build modular and solid skid systems. Doesn’t matter if it’s a small job or some huge setup — we keep it efficient and cost-effective.

Each skid structure is its own thing. That’s why our skid design engineers don’t just copy-paste stuff. We look at your space, what you’re putting in there, the weight, and how it’s all supposed to run. From first ideas to the final plan, we do it all — and we care about doing it right.

Skid Engineering Experts

So, like, our team? We totally build all sorts of stuff, from super simple to really complex skid-mounted systems. We make these really strong 3D models that show, like, the whole structure, plus all the piping systems, even the gear components, and those cable trays. We use these fancy tools to add in all the loads, what materials it’s made of, and where all the supports go.

Our skid engineering services do these strength assessments, and like, heat stress evaluations, and even shaking tests. Our team makes sure all these systems – yep, even the structural skid design, the compressor skid design, and the gas metering skid design – work safe and, like, really good out in the field.

Our Key Skid Design Capabilities

Piping Skid Design

Steel Skid Design

Modular Skid Design

Skid Structure Design

Structural Skid Design

Compressor Skid Design

Gas Metering Skid Design

Skid Drawing and Detailing

Skid Package Design & Layout

Equipment Skid Design

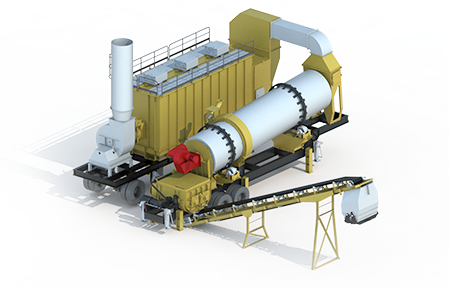

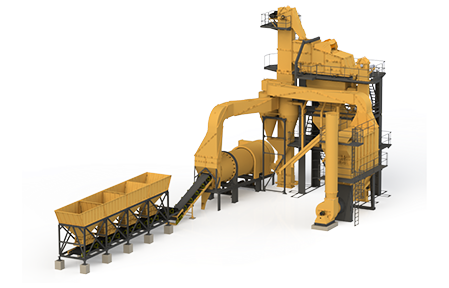

Skid Engineering Animation Videos

We make skid animation videos that show how your system works. These videos help a lot with client approvals, training stuff, and marketing too. They show real-time moves, what’s going on inside, and how strong the setup is.

We mix real engineering info with visuals to help people see what’s going on in the skid. Our animation services give you full-angle views and results that look super real. They’re a smart thing to use before building or setting it up.

Why Choose NEOCENT for Skid Design Services?

Get stuff built quicker at the site

Spot design mess-ups early, skip redo

Don’t waste stuff, save some money

Keep it safe and easy to fix

Show things clearly, get yes faster

Good designs that tick all the rules

Skid experts who use cool tech

Our Engineering Strengths in Skid Systems

Structural Skid Design

We really get into skid frames to make them super tough. They totally hold all the heavy stuff. Our team makes sure they’re strong, steady, and last a long, long time. No wobbles, ever.

Dynamic Load Response

We see how the skid moves when it shakes, or if machines hit it. We want it to run super smooth, even when things get wild.

Thermal & Stress Analysis

We check out heat and all that push on things so nothing breaks. Our plans think about heat expansion, pressure changes, and other outside pushes. Gotta be ready for anything.

Skid Modelling in CAD

We use cool programs like SolidWorks and AutoCAD to build awesome 3D skid models. These help people see the final thing and decide way faster. Super helpful.

Fatigue & Crack Prevention

We pretend things get used over and over to guess where tiny cracks might pop up. That way, your skid system lasts way, way longer and stays safe.

Skid Design & Analysis

Services We Offer

Static and Dynamic Load Calculations

Okay, so first we figure out how much weight your skid can handle—both when it’s just chilling (that’s static) and when it’s getting bumped around (that’s dynamic). This way, we make sure it won’t fall apart when you use it.

Piping and Equipment Layout

We’re basically like Tetris masters for pipes and equipment. We arrange everything so it fits perfectly without putting weird stress on the joints. More space, fewer problems.

Fabrication-Ready Drawings

Our drawings are so clear, even your newbie fabricator won’t get confused. We mark every weld, bolt, and material, plus throw in step-by-step setup instructions. No guesswork here.

Vibration & Fatigue Testing

We beat up your skid (virtually, of course) to see where it might crack or wear out over time. Think of it like stress-testing a phone case—but for heavy-duty stuff.

Composite & Custom Design Support

Special materials? Weird custom design? Cool, we’re into that. We’ll model it exactly how you need so nothing gets lost in translation. No cookie-cutter solutions here.

Why Pick NEOCENT for Skid Projects?

Honestly, we just help you save time, your hard-earned money, and a bunch of headaches on your skid projects. How? Simple. We come up with smart designs, get things done super fast, and give you really, really detailed reports. So you’re never, ever left guessing. It’s pretty straightforward, right?

- Global Support (Your Info's Safe Too)

- Engineers Who Actually Know Their Stuff

- We Handle Everything From Start to Finish

- Fewer Test Runs = Way Less Trouble

- Projects Done Faster, Less Going Back-and-Forth

- Oil & Gas? Chemicals? Yeah, We've Done It All