Finite Element Analysis Engineering Services

NEOCENT is a group of skilled FEA consultants. We use the latest tools to test how things will hold up under stress, heat, and pressure. Our FEA services help ensure that products are safe and reliable before they’re built.

At NEOCENT, we know that every project is different. That’s why our FEA consulting engineers provide custom solutions to meet your needs. We offer the best in Finite Element Analysis Consulting at a price that works for you. Our team uses the right tools and standards to get the job done.

FEA Consulting Engineers

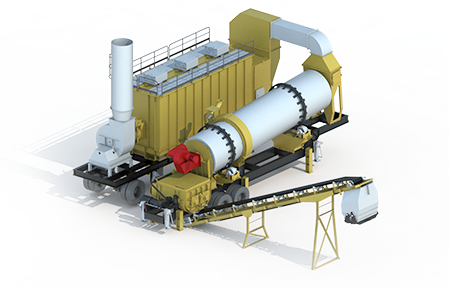

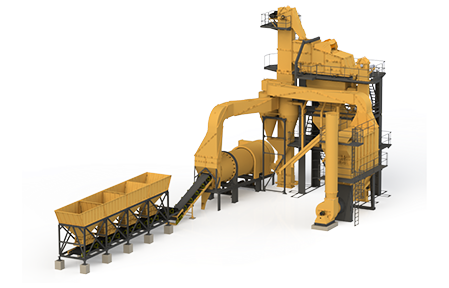

We make easy or tough models for simulation. Our team builds 3D models that act like stuff in real life. We use top software to add mesh, load, boundary, and material settings. This helps us get results that are close to real tests.

Our FEA engineering consultants check how strong the parts are and how much stress they can take. We also look at vibrations, fatigue, and cracks so things last longer. From small parts to big builds, we make models that act like the real deal.

Our Key FEA Capabilities

Linear & Static Analysis

Dynamic & Impact Analysis

Thermal & Heat Transfer Analysis

Fatigue Life Prediction

Fracture & Crack Propagation Analysis

Non-linear & Contact Analysis

Composite Material Analysis

FEA Modelling

FEA Animation Videos

We make FEA animation videos to show how your product works. These are super helpful for marketing and showing stuff to clients. The videos show what’s going on inside your design when it’s under pressure.

We mix cool animation with real engineering to show how it performs. This way, it’s easier for you and your clients to get it. You get full 360 views and real-like effects, so every part is clear. These videos are great before launch or even before building your first prototype.

Why Choose Us for FEA Services?

Save money by cutting down on extra prototypes

Get your product to market faster

Spot design issues early

Check how it works before you build it

Make sure it’s safe and meets all quality rules

Help your product last longer

Work with smart FEA consultants and cool software

Get global help with safe data systems

Our Engineering Strengths in FEA

Dynamic FEA

With our dynamic FEA analysis, we see how stuff handles shaking, impacts, or moving fast. Our FEA consulting service helps you figure out how it reacts over time and keeps it safe when it’s in motion.

Structural FEA

Our finite element analysis consultants run cool tests to see how your parts hold up under pressure. We help stop stuff from breaking and save material with super accurate FEA modelling services.

Fatigue & Fracture FEA

Our finite element analysis consulting team finds out when and where cracks might start. That way, your parts last longer and don’t fail when things get rough.

Thermal FEA

Too much heat can mess things up. Our FEA consulting engineers check how heat moves through your part and where it gets too hot. We make sure it works fine in both hot and cold spots.

Non-linear FEA

Real-life stuff is messy. Our FEA engineering consultants use non-linear simulations to see how things act when bent, twisted, or pushed super hard, so nothing breaks when it matters most.

FEA Analysis in SolidWorks

Want to test stuff right inside your CAD? We use FEA analysis in SolidWorks for fast results without leaving your design. It’s quick, saves time, and helps cut down on rework.

Finite Element Analysis Services We Deliver

Neocent Engineering Offers

Static & Dynamic Load Analysis

This Finite Element Analysis (FEA) service makes sure stuff works like it should and doesn’t mess up. Our FEA consulting service team jumps in fast with the right skills, so you can get your product out there quicker.

Thermal Analysis for Steady State and Transient State

We use thermal analysis to check how heat spreads around in your design. This helps make sure the part can handle heat inside and outside, no problem.

Mechanical Stress & Strength Analysis

Our FEA team looks at the structure and checks if things like cost, weight, strength, materials, and size all add up. Then we run a few simulations to see if the design can actually hold up.

Fatigue, Crack & Life Cycle Analysis

We test how tough the design is in all kinds of situations. Static, dynamic, thermal — whatever it is, our team sees if your product’s built to last.

Composite & Layered Structure Simulation

We run dynamic and composite analysis to see if the design updates actually work. Gotta make sure it’s solid when people use it for real.

Benefits of Outsourcing Finite Element Analysis Services to Neocent Engineering

Neocent Engineering helps with design, modeling, and analysis for mechanical products. We know the latest software and testing tools. That’s why we’re a good fit for your FEA needs. Here’s why outsourcing to us works:

- We work with clients all over. Our quality is solid and our process is safe.

- You save money. No need to hire skilled staff or buy expensive tools.

- Our team knows all the top FEA software and tools.

- We catch design issues early. You won’t need to redo things later.

- We help make sure your design is strong and won’t fail.

- We’ve worked with lots of industries. We’ve seen all kinds of projects.