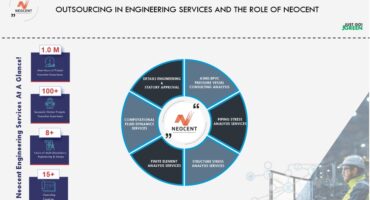

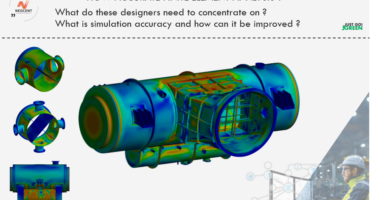

Specialized Engineering Services

Neocent Engineering provides specialized engineering services such as stress analysis for both greenfield and brownfield designs. Our team is comprised of engineers who are equipped with the expertise to perform stress analyses on new models as well as on existing plans for industries such as oil & gas, refineries, petrochemical & chemicals, renewables, pharmaceuticals, mining, manufacturing, fertilizers, and utility industries such as water and effluent treatment and power.

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry codes and standards are adhered to by our Designers.

ASME, BPVC Division 1 (Rules for the Construction of Pressure Vessels), ASME Pressure Vessels for Human Occupancy (PVHO), ASCE 4-98 and ASCE 7-02, AISI N690, ABS Underwater Vehicles, Systems & Hyperbaric Facilities.

Man-Hours of Project Executed

Years of Team Experience

QMS certification

Service Offering

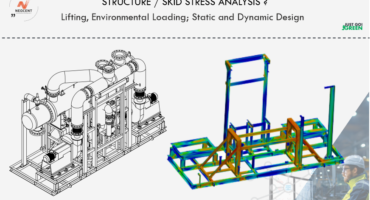

The process also involves structural design calculations for the estimation of environmental loads (e.g., ice, snow, wind, rain, seismic), equipment, and operating loads.

What To Expect When You Work With Us

Trusted Expertise

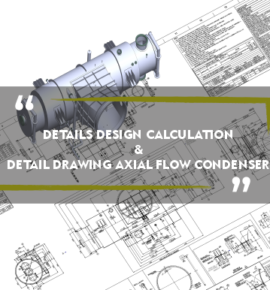

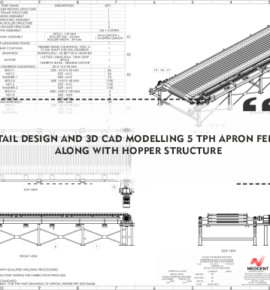

We have the backing of our hundreds of clients to showcase our expertise in Equipment Mechanical and thermal Design, Equipment Stress Analysis with Applicable code, Piping Stress Analysis, Structure Stress Analysis, Skid Design/Analysis Package, and Fluid flow simulation services.

Innovative Engineering Solutions

Through our proficiency in designing, we solve complex business challenges for optimizing space and executing faster plant upgrades.

24X7 Support

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

Scalability

We have expertise in performing stress analysis on new plants as well as existing models for different industries.