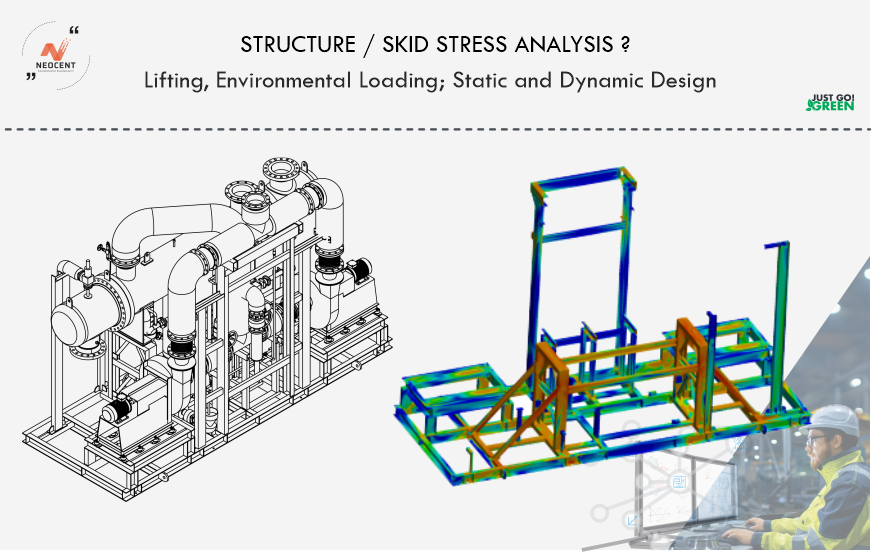

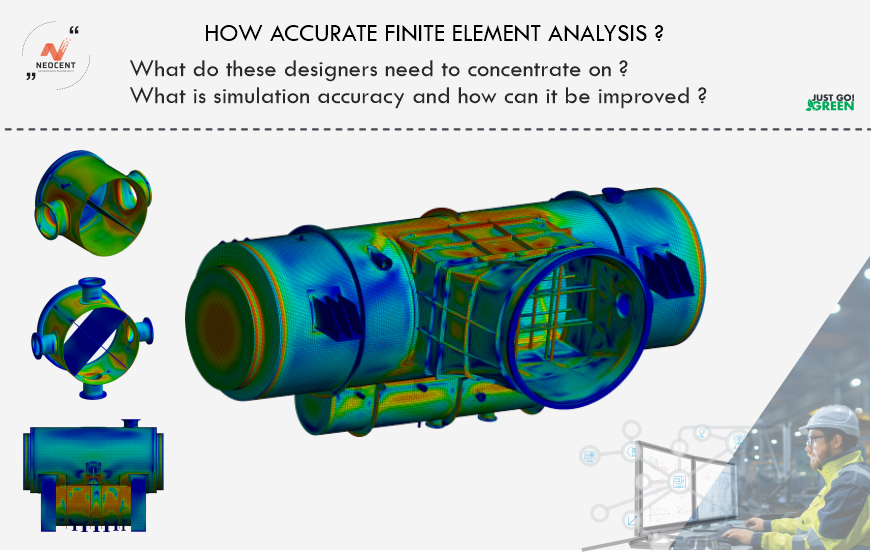

Finite Element Analysis Engineering

FEA is beneficial to any project that requires strength, durability, or dynamics analysis. It is frequently used to investigate design changes for cost, weight, manufacturing, benchmarking, or performance reasons, and can provide early confidence in designs prior to undertaking expensive and potentially destructive test regimes.

The technical expertise of our FEA consultants in delivering Finite Element based product design optimization enables you to address complex engineering design problems and help validate product designs prior to production.

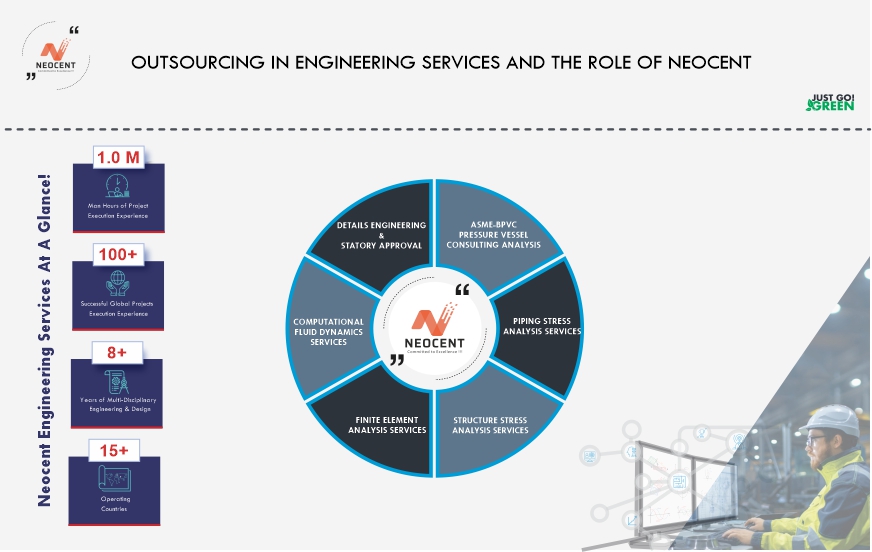

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry codes and standards adhered to by our Designers.

ANSI, AISC, UBC, IBC, ASCE, ACL, BS, IS, ASME, AISI, ABS.

Man-Hours of Project Executed

Years of Team Experience

QMS certification

Service Offering

What To Expect When You Work With Us

Staying in-Tune with Latest

We stay updated with the latest versions of software and adhere to the industry codes & standards to provide sublime assistance during the project bidding phase.

Innovative Engineering Solutions

Through our proficiency in designing, we solve complex business challenges for optimizing space and executing faster plant upgrades.

24X7 Support

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

Scalability

We deliver the Finite Element Analysis and engineering solutions to both the small and large scale projects, even in a short notice period.