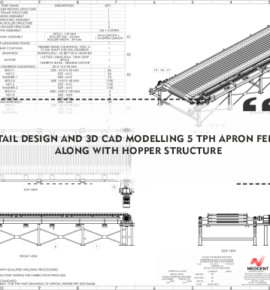

Equipment Engineering

Neocent Engineering’s static equipment engineering services comprise the design and analysis of pressure vessels, storage tanks, heat exchangers, and boilers. Our proficient team of qualified engineers has experience across industrial equipment and engineering companies in managing a wide range of projects for customers from petroleum refineries, chemical plants, petrochemical plants, pharmaceutical plants, food processing plants, wastewater plants, reactors, condenser, evaporators, and more.

We are the preferred choice for organizations from around the world for equipment design with high-quality performance, quick response time, and acute knowledge of international codes and standards like ASME Section VIII, API & TEMA for industrial equipment engineering services.

Industries Served

Oil & Gas

Petrochemical & Refinery

Energy & Utility

Specialty Chemical

Manufacturing

Water & Waste Water Treatment

Industry codes and standards adhered to by our Designers.

API 650, API 579, API 620, API 653, ASME Boiler & Pressure Vessel Code, Section VIII, Div. – 1 & Div. – 2, PD 5500, TEMA

Man-Hours of Project Executed

Years of Team Experience

QMS certification

Service Offering

Storage Tank Design

- Storage tank design as per codes API 650, API 620, and API 653

- Floating roof tank design

- Fixed roof tank design

- Design validation

- Design of tank structure

- Mechanical equipment selection

- Relief valve sizing, calculation, and selection

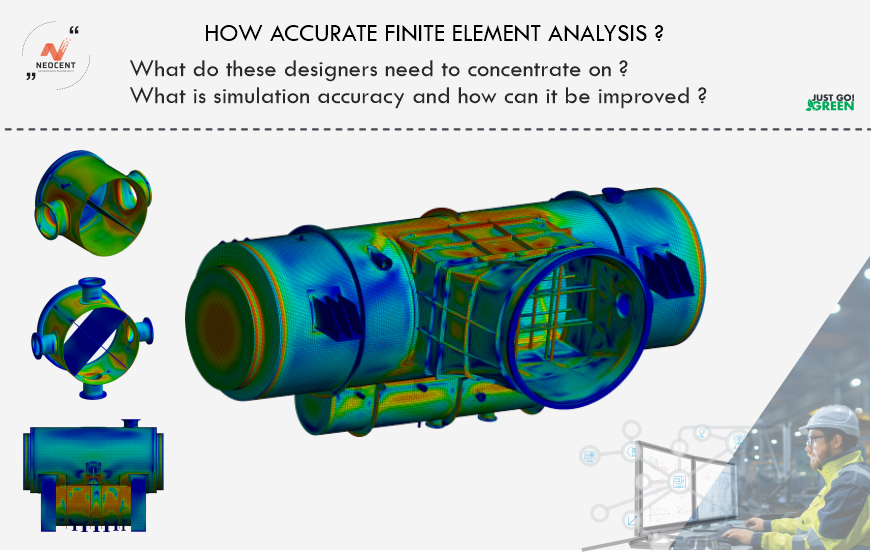

Pressure Vessel Design

- Configuration and analysis of pressure vessels (columns, horizontal & vertical pressure vessels, spherical vessels, reactors, etc.) according to the ASME Boiler & Pressure Vessel Code, Section VIII, Div. – 1 & Div. – 2

- Calculation of minimum retirement thickness values for existing pressure vessels and their components so as to maximize safety and increase durability

- Predictions to check the suitability of vessels for in-situ PWHT (post-weld heat treatment)

- Fatigue analysis to estimate and analyze the life of pressure vessels subjected to pressure, temperature, and startup/shutdown cycles

- Failure analysis to identify the cause of failure of failed pressure vessels and their components

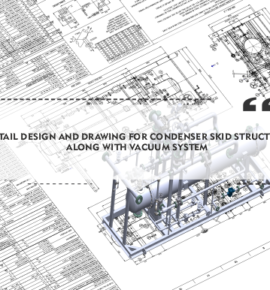

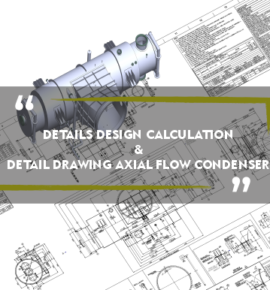

Heat Exchanger Design

- Design of heat exchangers according to the TEMA and ASME Boiler & Pressure Vessel Code, Section VIII, Div. – 1

- Calculation of minimum retirement thickness values for existing heat exchangers and their components so as to maximize safety parameters and increase durability

- Tube-sheet thickness calculations for different types of heat exchangers

- Calculations for other heat exchanger components such as channel covers, floating heads, etc.

- Calculations for fixed tube-sheet heat exchangers

- It is possible, with or without flanged and fluid expansion joints, to conduct a re-rating and fitness-for-service evaluation

What To Expect When You Work With Us

Seamless Integration

With our expertise in modern tools & technologies, we help global EPC organizations with the implement the latest applications in their existing infrastructures without facing problems.

Innovative Engineering Solutions

Through our proficiency in designing, we solve complex business challenges for optimizing space and executing faster plant upgrades.

24X7 Support

Our customer service is available round the clock to solve your queries. So, don’t hesitate to reach out to us anytime.

Scalability

From petroleum refineries to pharmaceutical companies, and from chemical industries to food processing plants, we offer static equipment engineering services across a wide range of projects.